HISTORY

Our company has been working in the vegetable and herb processing industry since 1948 and also in the medicinal herb sector since June 1951.

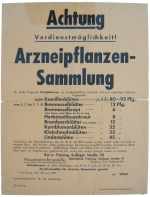

There we started a poster campaign in Bavaria to gather health supporting and medicinal herbs.

Our company has been working in the vegetable and herb processing industry since 1948 and also in the medicinal herb sector since June 1951.

There we started a poster campaign in Bavaria to gather health supporting and medicinal herbs.One original poster is still decorating our company portal. You can see it in the picture on the right.

1957

In a town named "Freising" in Bavaria we built our first dryer for vegetables and herbs. The former General Manager, Mr Anton Völpel, father of the today's General Manager Dr Dagobert Völpel, caused the construction of the first dryer burning oil instead of coal world wide. Together with a local construction company we built a far improved dryer for herbs and vegetables two years later. This was a milestone in drying plants at this time.1970

Our company dislocated from "Freising" to "Königsmoos", which is still our place. The company in "Freising" was still run for a few years in order to expand faster and more systematically.1972

After his graduation Dr. Völpel entered actively on our company.1979

The first Bavarian dryer for vegetables using natural gas and with US-technology in Germany was constructed in addition to existing plants.1982

A new office building of 500 square metres and two store houses with 2,000 square metres were built.1989

We enlarged our list of items with a new sector: Dehydrated vegetables, dehydrated herbs, dried apples and herb-teas as well as fruit-teas, all taken from controlled biological cultivation.At the same time we got certified according to the rules of EEC 2092/91 and for working with Biotop Herbs (naturally developed and/or kosher).

1995

Using all our own resources and supported by the advice of authorities we made the biggest investment in our history. We built another new dryer as well as a new herb and vegetable mill and a new mixing machine.1997

We got another certification. That year we got certified internationally according to ISO 9000 in the EQ-Net and in Germany according to DIN EN 9001:2008.1998 und 1999

We built in a heat recovery plant. In the international trade press this energy-compound is labelled as an optimal solution, for example in the trade magazine "Gaswärme International", issue 10/2002.On top of those big investments we built the first combined heat and power unit in the Donaumoos in the year 1999. So we produce our own electricity in an environmentally compatible way. The rejected heat warms water up to 80°C. This water stokes the drying department and the offices and supplies them with warm water at the same time. In this way we can save energy and emissions equivalent to the estimated consumption of 80 detached houses.

Because of this we were awarded a 3rd prize for ecology and economy by the cooperative banks of our district. Of course a fundamental part of our company's philosophy - sensible pollution control - was made stronger by this fact.